Wireless Sensor and Actuator Networks (WSANs) have proven great flexibility and convenience for monitoring and interfacing the digital world with the physical world.

The small footprint, ease of deployment in inaccessible situations, low cost, and reduced energy consumption, make WSANs a unique candidate for an ample field of applications.

Industrial manufacturing scenarios can employ the feature-rich WSANs for effective observation and control of physical production processes.

However, in the considered scenario, the operations and interactions of the different processes must be extremely accurate, and therefore, the dependability of the system is of utmost importance.

Dependability in WSANs

The Wireless Sensor Network (WSN) in the BEMO-COFRA system aims to realize a dependable network, via the integration of the following features:

• Context awareness: The network features a Frequency-Agility (FA) service, enabling the nodes awareness of the current spectrum conditions, as well as providing the best available operating channel whenever a channel switch is necessary. • Context awareness: The network features a Frequency-Agility (FA) service, enabling the nodes awareness of the current spectrum conditions, as well as providing the best available operating channel whenever a channel switch is necessary.

• Cooperation and detection: Cooperative sensing procedures are adopted in order to ensure information reliability against outliers, and to distribute the workload for energy efficiency. Real-time monitoring of the available channels is performed by spectrum sensing, furthermore, internal network health is monitored, thus keeping track of packet losses and end-to-end delay. • Cooperation and detection: Cooperative sensing procedures are adopted in order to ensure information reliability against outliers, and to distribute the workload for energy efficiency. Real-time monitoring of the available channels is performed by spectrum sensing, furthermore, internal network health is monitored, thus keeping track of packet losses and end-to-end delay.

• Self-configuration and self-healing: Network discovery mechanism is executed at startup and/or after a network failure. Furthermore, a network manager is available, assigning roles to the different connected nodes as required by the application. • Self-configuration and self-healing: Network discovery mechanism is executed at startup and/or after a network failure. Furthermore, a network manager is available, assigning roles to the different connected nodes as required by the application.

Equipped with the aforementioned features, the WSN of BEMO-COFRA is expected to fulfill the following dependability requirements:

• Availability: by maximizing the time during which the network end-to-end connectivity is up and running, providing sensing information, data, etc., at the receiving end. • Availability: by maximizing the time during which the network end-to-end connectivity is up and running, providing sensing information, data, etc., at the receiving end.

• Robustness: by ensuring that the system functions correctly under - and reacts properly to - abnormal conditions, thanks to the FA service. • Robustness: by ensuring that the system functions correctly under - and reacts properly to - abnormal conditions, thanks to the FA service.

• Reliability: by ensuring the correctness of the received information in terms of content and timing, thanks to the cooperative monitoring. • Reliability: by ensuring the correctness of the received information in terms of content and timing, thanks to the cooperative monitoring.

Frequency-Agile WSN System Architecture

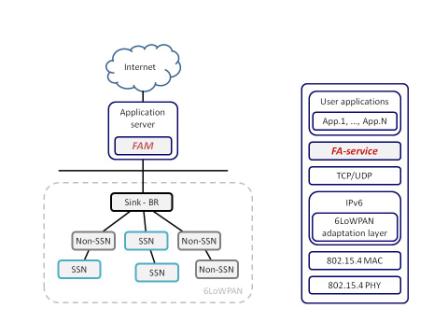

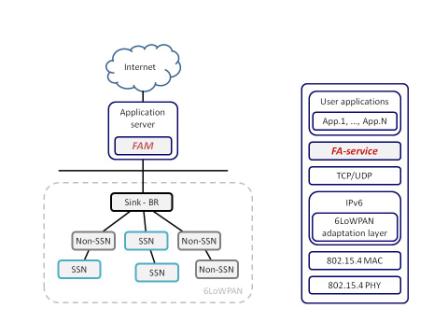

The figure below shows the reference system model for the WSAN, operating with a 6LoWPAN stack and provided with FA extensions. The WSAN features RPL as the routing protocol, where an RPL Border-Router (BR) is deployed that acts as a sink node, and moreover, it manages the two-way data between the 6LoWPAN and the Application server. In the 6LoWPAN based WSAN, nodes can be either Spectrum Sensing Nodes (SSNs) or Non-SSNs. SSNs perform spectrum sensing on the available radio channels and do not participate in the application, while Non-SSNs carry out network application functions and do not participate in spectrum sensing.

All WSAN data are communicated to the application server for processing, while spectrum sensing information is further processed at a component called the Frequency Agility Manager (FAM). The FAM processes the spectrum sensing data and obtains the spectrum occupancy state. If the FAM determines that a critical level of interference is present in the current operating channel (OC), it generates an OC switch command to reallocate the network to the best available channel.

In order to provide individual nodes with FA capabilities, the 6LoWPAN stack is extended with an FA service, as shown in the figure to the right. The FA service manages the FA-related operations and routines in the local node; in addition, it reacts to the various commands arriving from the FAM.

Please note that the data acquisition process by the sensor nodes and the information transfer to the FAM are all performed in real time.

Within the BEMO-COFRA context, Non-SSNs can have two responsibilities:

• Skid orientation monitoring: Leveraging on the onboard 3-axis accelerometer sensor, a node that is affixed on the skid, constantly provides accelerometer readings to the server, thereby determining the orientation of the skid during the manufacturing process. • Skid orientation monitoring: Leveraging on the onboard 3-axis accelerometer sensor, a node that is affixed on the skid, constantly provides accelerometer readings to the server, thereby determining the orientation of the skid during the manufacturing process.

• Robot gripper state monitoring: A sensor node is mounted on the robot arm to detect whether the gripper is locked or unlocked. The sensor node leverages on a mechanical button that is attached to the node through an extension wire, and placed inside one of the gripper’s two pads. • Robot gripper state monitoring: A sensor node is mounted on the robot arm to detect whether the gripper is locked or unlocked. The sensor node leverages on a mechanical button that is attached to the node through an extension wire, and placed inside one of the gripper’s two pads.

to

the top  |

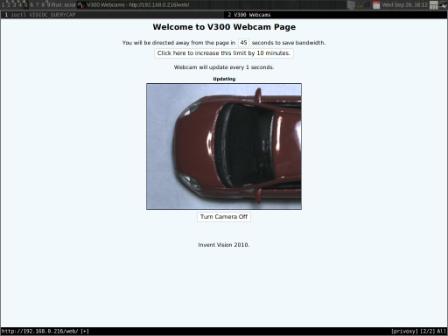

The picture (left) illustrates the setup composed of a wireless smart camera pointing to where a car body is present. The software embedded in the camera is able to identify the position of the car body and send a signal if the position is correct. The software is based in the segmentation of the car body. This segmentation depends on the colour of the object to be inspected, in this case the car body.

The picture (left) illustrates the setup composed of a wireless smart camera pointing to where a car body is present. The software embedded in the camera is able to identify the position of the car body and send a signal if the position is correct. The software is based in the segmentation of the car body. This segmentation depends on the colour of the object to be inspected, in this case the car body.